For Visitors

No: 8/126A14, Rice Mill Street,

Aralvaimozhi - 629 301,

Tamil Nadu, India.

No: 8/126A14, Rice Mill Street,

Aralvaimozhi - 629 301,

Tamil Nadu, India.

Our team of expert technicians will work on the improvement of wind turbine blades. Turbine performance and blade condition are critical to improving the efficiency of wind farms and wind power generation. With a record of excellence in blade services, we have the best experience to support any kind of complex blade project.

Our projects range from single-blade repairs to large turn key-blade repair projects. Our team is experienced in performing warranty updates and post-production services for specific blade models.

Prevention is better than cure. It's better to protect the blades with good maintenance beforehand than to be at a loss without maintaining them. Wind turbines have an overall lifespan of 15 years, but the lifespan of surface coatings is not as much as that. Using rope techniques, we'll distinguish the damage caused by the blade.

Wind composite provides a safe, stable, and cost-effective way to do blade maintenance work. Planned inspection and maintenance strategies prolong the life of a turbine and secure reliability for the full lifecycle.

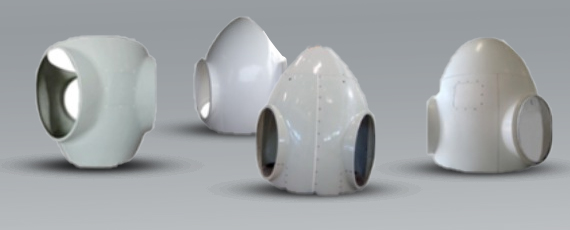

It is an enclosure made of glass fibres reinforced polyester resin, equipped with all necessary fitting accessories and electrical connections to fit the hub casting structure of wind turbine generator with reference to customer specifications and requirements.

It is an enclosure made of glass fibres reinforced polyester resin, equipped with all necessary accessories like cooling arrangements including the cooler motors, radiators & exhausts equipped with acoustic insulation, electrical connections including tube lights and smoke detectors, fireproofing insulations,safety hangers and required mechanical support structures to fit the base frame structure of wind turbine generator with reference to customer specifications and requirements. A notable feature now found on some off-shore wind turbines is a large sturdy helicopter-hoisting platform built on top of the nacelle, capable of supporting service personnel and their tools, winched down to the platform from a helicopter hovering above it. Wind turbine rotors are stopped, feathered and locked before personnel are dropped down to or picked up from the platforms.